A good knife is truly a thing of beauty. Slicing through a potato like it’s butter not only feels incredibly satisfying, but also saves an enormous amount of kitchen prep time. It might seem like a pretentious notion to wish that every household had a good-quality knife (especially as they don’t always come cheap) but a sharp, strong knife can really make the difference between dreading cooking and loving it, shaving hours off the boring bits and leaving more time for the creative stuff.

While we might automatically associate knifemaking with countries such as Germany, Switzerland and Japan, knives have actually been made in New Zealand for the last century, albeit with a much stronger focus on hunting, fishing and meat processing. But the last few years have seen a wave of artisan knifemakers creating beautiful products for a market with a renewed enthusiasm for the home kitchen.

Skye Eilers is part of the team that runs the Auckland Blade Show and a culinary knifemaker himself, and he’s really noticed the trend. “Culinary knives are actually a relatively new focus for the knifemaking community worldwide. It was only in 2019 that the Blade Show Atlanta – the largest knife show in the world – added kitchen knives as a category for awards of custom knives.” Gareth Hughes, the fourth owner of Victory Knives – which has been around in New Zealand since 1927 and now produces 3000 plus units a week – agrees. The company has changed focus many times since its inception: from knives for butchers, to knives for the forces in World War II, to hunting and fishing knives, to supplying the meat processing industry in freezing works and butcheries. “There’s definitely been a swell in the last five to ten years, probably in line with the whole artisanal craft movement. While it’s not our main focus, we’re definitely selling a lot more blades to makers who go on to create really fancy handles and make beautiful knives for people’s kitchens. And, of course, cooking has changed so much, including the huge interest in barbecue in recent years – people need more knives now, one for trimming sinew, one for their brisket, one for dicing.”

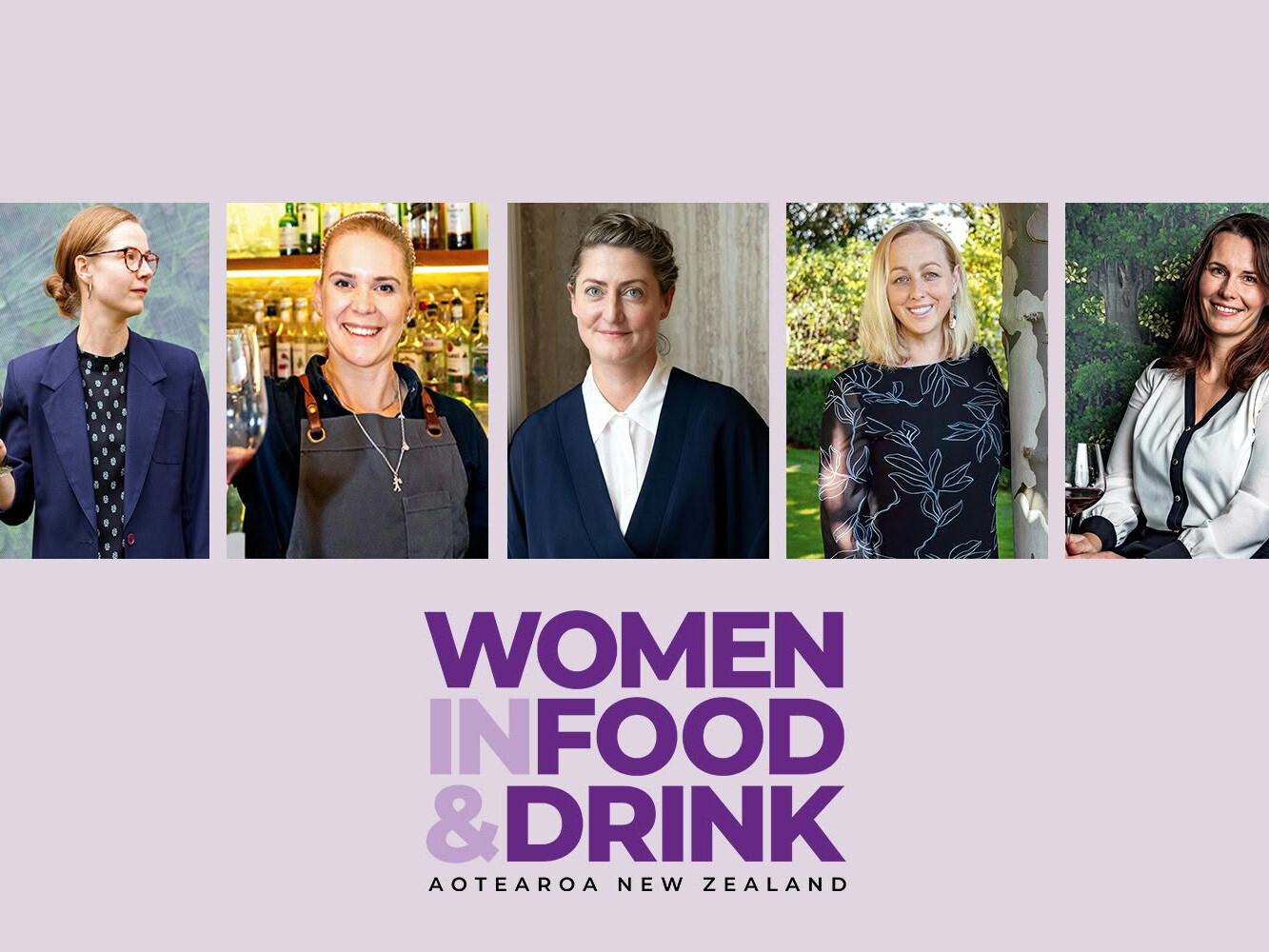

We spoke to four knifemakers who have recently started new businesses and have no shortage of interest in their stylish kitchen implements.

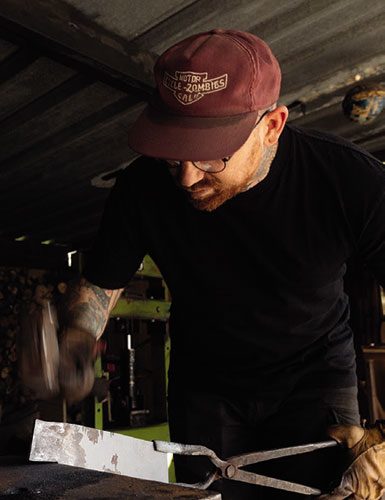

HAYDEN SCOTT,

AUCKLAND

Hayden Scott worked with well-known chef Al Brown for 15 years, in restaurants, at events, on cookbooks and travelling with him as he filmed some of his TV series. While filming in Tasmania, they met a knifemaker in the bush creating knives out of recycled bandsaw blades from sawmills. Hayden was instantly hooked and this sowed the seed for his own brand, Champion Knives.

“It’s no huge surprise I’ve ended up making something for a living. I grew up in Balclutha around people who made all sorts of things. There was always someone tinkering with motorcycles, restoring bicycles, furniture… We didn’t have a whole lot growing up so everything was made. Mum sewed or knitted all our clothes, and my uncle even built airplanes in his garage!

“I’ve worked as a chef for a long time: 25 years in Edinburgh, Vancouver, Dunedin, Wellington and Auckland, 15 of those years with Al. When we met the knifemaker in Tasmania, I was awestruck and when I got back home I made an oyster shucker from steel I found under the house. It kind of just went from there and now I’m finally doing it full time.

“My style reflects the environment the knives are made in – dark and battered – as they are hand-forged. I prefer to work with carbon steel and make my own patterned steel. I really believe these materials allow the knives to take on a life and character of their own and I intentionally leave some of the scarring so you can see how it’s been made. It’s funny, on the surface people see knifemaking as dangerous and a hostile environment, but when you’re working with 900-degree steel you really have to concentrate and that focus is almost meditative – there’s a real peacefulness about it.

“I find it endlessly fascinating to take raw materials and teach yourself techniques to transform them, but there’s a real personal connection with knifemaking that people may not know about. I love it when I can connect someone to the person who has given them the knife or something that has meaning or is sentimental for them, like a handle made out of a fencepost from the farm they lived on. I’ve actually just made several knives for someone from a marlin bill! I feel so grateful I get to put these objects out into the world.”

championknives.co.nz

instagram.com/championxknives

MADISON BAKER,

WAIUKU

Madison Baker has knifemaking in her blood, but never imagined she would actually follow in her father Bryan’s footsteps. She did mechanical engineering at university and pursued a career in aviation, but COVID had other plans for that industry. A dining-room conversation with her dad when she was back at home over lockdown, led to the eventual creation of Nůž, the knife brand she runs with her sister Kelsey.

“I’ve grown up with knives around me. Dad started his company, SVORD, 40 years ago but I’m not a hunter or avid fisher so I couldn’t imagine myself going into the family business. He got interested in knives after doing a metalwork class where they made one, but his business really took off after he met an elderly Czech knifemaker who showed him his traditional manufacturing style. The name of our company (the Czech word for knife) is definitely a tribute to him. It’s come full circle.

My sister Kelsey does the hands-on stuff. She’s really talented on the tools, I’m more the problem-solving business side of things. Our business has a strong focus on sustainability: the blades are made from recycled carbon steel and the handles are FSC-certified wood. We’ve offset all the emissions of manufacturing and make sure we really understand the lifestyle of all the materials involved. Our goal was to create a minimalistic, sleek kitchen knife in a modern design that was durable enough to last a lifetime.

“We launched last April and sell direct online, but we’ve also got into some retail places in New Zealand and Melbourne which is pretty exciting. Of course Dad’s super-stoked to have both daughters involved in knifemaking, when that really seemed unlikely only a few years ago. One of our biggest goals is to try and bridge the gap between sustainable and affordable when it comes to kitchen knives. Sometimes it seems there always has to be a trade-off, but why should it have to cost so much to buy something that’s better for the environment? We want to demonstrate it can be done and help shift that trend.”

nuz.nz,

instagram.com/nuz_nz

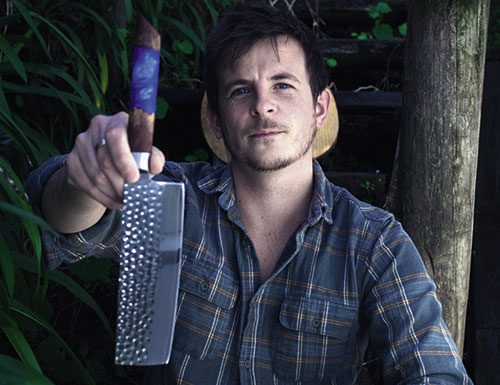

SAM STEWART,

QUEENSTOWN

Sam is no stranger to us here at Cuisine. As well as making beautiful knives he’s a talented photographer who regularly shoots food, restaurants and chefs for the magazine. His venture into making knives seems a natural progression; a creative born into carpentry, who has also worked carving pounamu, this is a beautiful melding of both his worlds.

“Creativity has always been important to me, from early on when I studied product design in Dunedin. I guess I learned processes to put ideas into action. But I’ve also always worked with my hands. I’m a carpenter, the same as my dad was, so I’ve always been around wood, always sourcing timber for jobs or repurposing pieces that I pulled out of renovations.

“I’ve always had a fascination with timber, especially our beautiful native ones. The knifemaking is a combination of my love for wood and making things and my love for food. My mum is a great cook and so is my aunty, and cooking feasts for friends and family is something I love to do. Once I started using a good knife, it got me thinking about how they are made, which led to figuring out the process and starting to make my own. There was a lot of obsessive watching of videos online and then I did a one-day course and made my first knife. I’ve done a couple more courses since then to really understand the technicalities.

“Getting into making knives to sell has been a bit more complex than I first thought. There’s a lot of equipment to buy, but I’m really happy with the style I’ve come up with and love making them. Selecting the handle material is quite a big part of the process. Finding a piece with the right grain to go with the flow and feel of the knife is really satisfying. I love the forged aesthetic in knifemaking. I use high-carbon steel and try to leave a bit of the forging history on the blade by forging it thin and to shape. And, so far, they seem pretty popular.”

instagram.com/knife.and.ember

SAM UPSHALL,

ŌHOPE BEACH

Sam Upshall lives across the road from one of New Zealand’s most beautiful beaches in Ōhope. He’s previously worked in building, roofing, tiling and carpentry but has been in hospitality on and off for the last 10 years. Some experimentation in a five-week COVID lockdown led to a love for making knives and the launch of a new business.

“I’ve always loved cooking, dining out and everything that food brings. All my family are fantastic cooks, my eldest brother became a chef at a young age and I’ve managed pubs in the UK, restaurants in New Zealand and worked as a barista in Australia. My partner and I spend lots of time looking after friends’ houses and animals while they are away, and I was so sick of cooking with blunt and poor-quality knives that I ended up taking my own everywhere we went. That’s when I realised there was a gap in the market for a quality knife – above that of your usual kitchen knife – but at a price that people can actually afford.

“I didn’t want to make the blades but I loved the thought of creating beautiful handles with hints of New Zealand in every design. I got in touch with many companies across the world to source a selection of different blade styles and materials – my kitchen is full of all the rejects now! I spoke to many of the chefs I’ve worked with to find out what they liked in a knife and which companies they use and tested many myself. Eventually, I found this beautiful Japanese high-carbon steel with Damascus cladding – it holds a brilliant edge and is easy to sharpen.

“For the handles, I wanted to create artworks you use every day so I used native timbers such as pōhutukawa, rimu and rewarewa and then blended these with resins and pigment powders to add New Zealand design touches like fired pōhutukawa flowers, ferns and pāua-shell pieces. For the first two years it was only custom work, but now I’m building up more stock. I’ve done everything from people’s national flags, embedded pieces of pounamu or even using timber recycled from their house renovations. One of the more unusual requests was a chef who wanted her knife to match her Air Jordan trainers and her red Mini Cooper!

newwaveknives.info

instagram.com/newwave_knives